Located at ERDC’s Cold Regions Research and Engineering Laboratory (CRREL) in Hanover, N.H., the Ice Adhesion Testing Facility is equipped to evaluate the performance of a variety of materials in multiple configurations and with a range of ice types and temperatures.

What it does

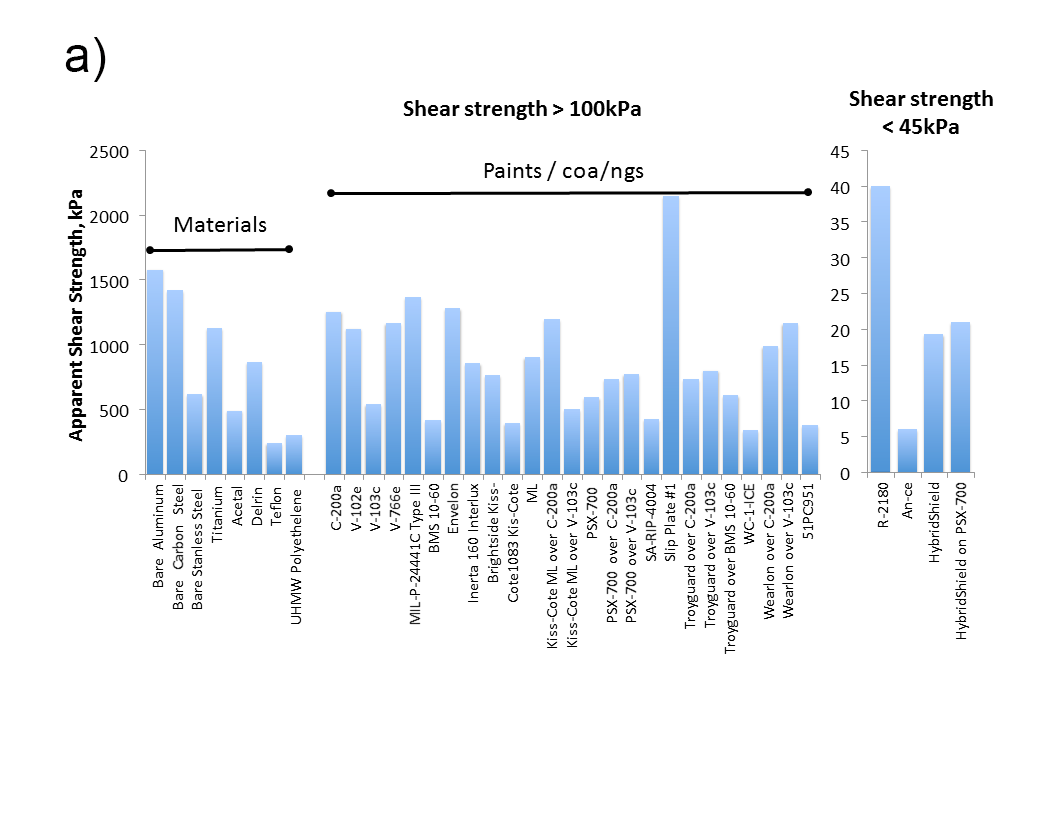

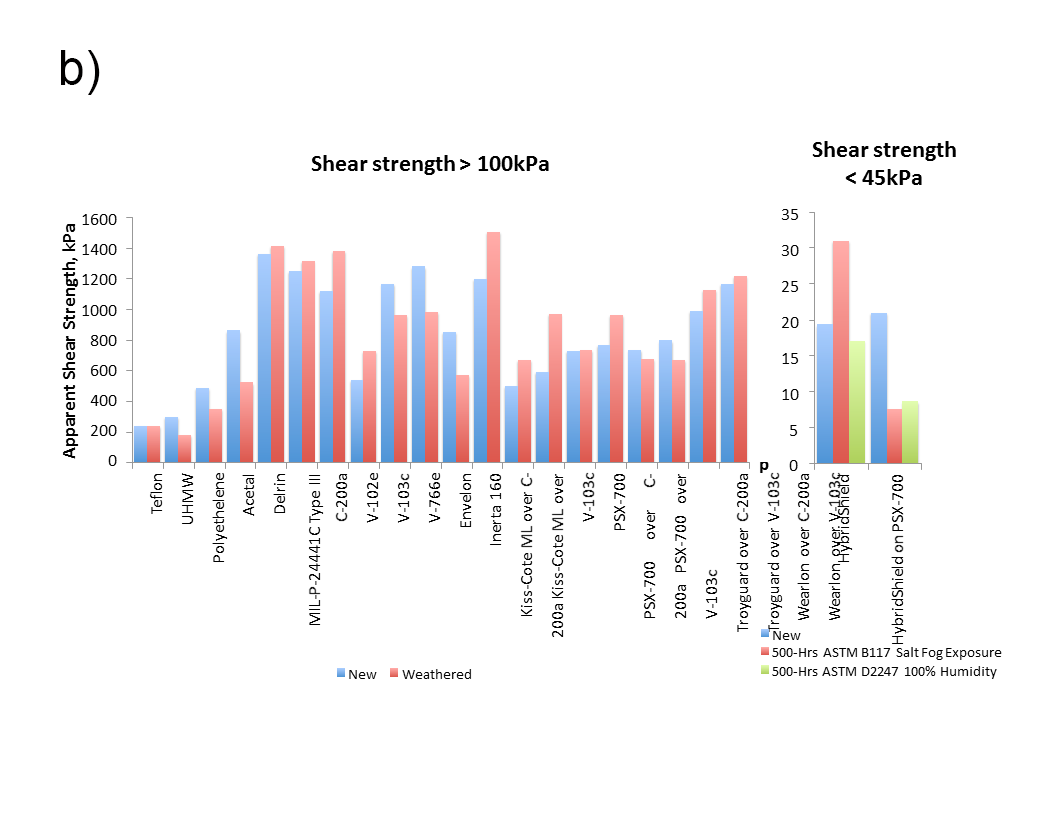

ERDC-CRREL has a long standing reputation in the evaluation of coatings and materials for low ice adhesion applications in locks and dams, aviation, maritime operations, and utility installations (Figure 1).

In addition to testing the adhesion of ice to freshly prepared surfaces, CRREL has also performed weathering tests to verify the durability of a broad range of coatings.1

As seen in Figure 2, there is not a consistent trend the in durability of coatings; some adhesion values have decreased while others increased and still others remained approximately the same.

More recently, CRREL has performed durability testing on polyurethane rubber coatings that showed remarkably low ice adhesion after outdoor winter testing and abrasion.2 Owing to the large data set of evaluated low ice adhesion coatings and materials it is easy to compare the performance of new coatings and materials to the performance of existing products.

Figure 1. (a) Ice adhesion test results for construction materials and commercial coatings. (b) Ice adhesion test result for potential low-adhesion coatings and materials before and after weathering. Samples on left were tested before and after being placed below water level in a Mississippi River navigation lock for a 4-month-long summer season where they were subjected to repeated draining and flooding with normal lock operations. The weathering processes for the data on the right are indicated in the legend. (References: EM 1110-2-1612 , Table 20-4, page 449)

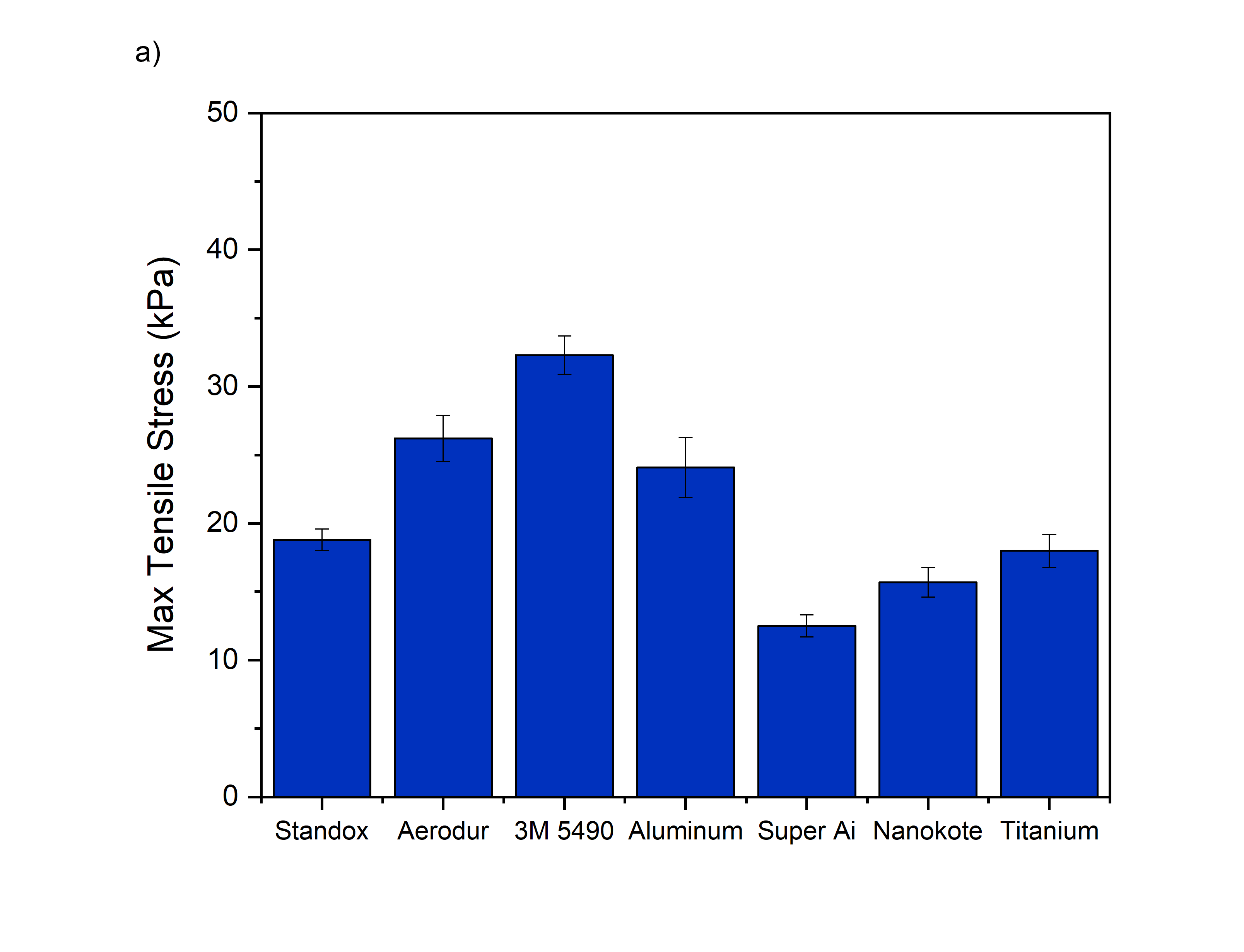

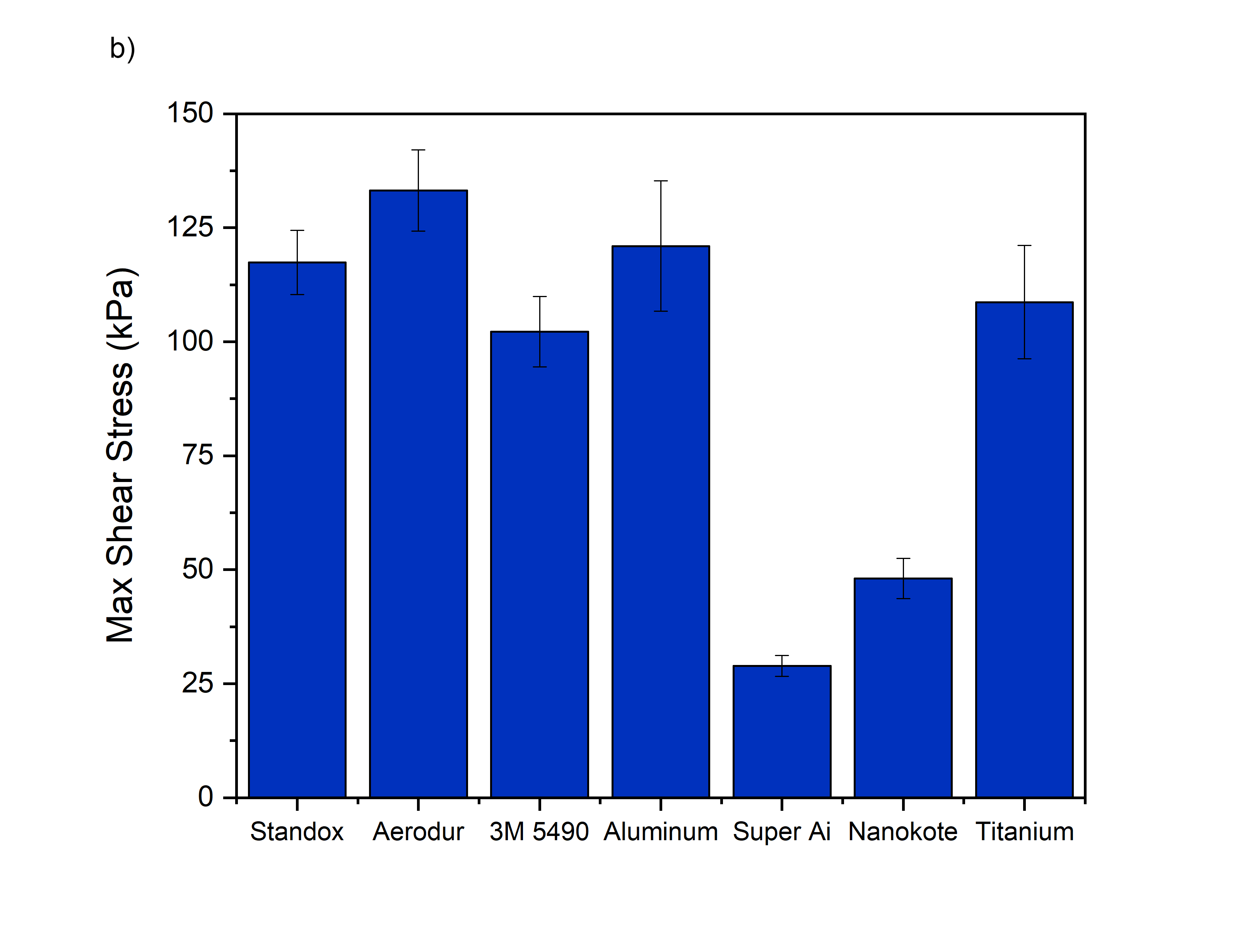

Figure 2. The apparent ice adhesion strength for commercial materials in (a) tension and (b) shear delamination modes at −8°C. Error bars represent the standard deviation of the average values. At least five replicates were used for each sample type. (References: ERDC/CRREL TN-21-1)

Features & Specifications

- Tensile (Mode I) or shear (Mode II) fracture modes

- Temperature capabilities range from −5°C to −40°C

- Flat or curved specimens, closed or open configurations

- Polycrystalline freshwater ice, saline, or freshwater spray ice

- Small- to mid-sized laboratory scale specimens (30 x 50, 100 x 150 mm) or large scale specimens (1 x 1 m) can be accommodated

- Weathering tests and durability testing available

A standard summary report is provided for each group of specimens tested. (Raw data files available upon request.)

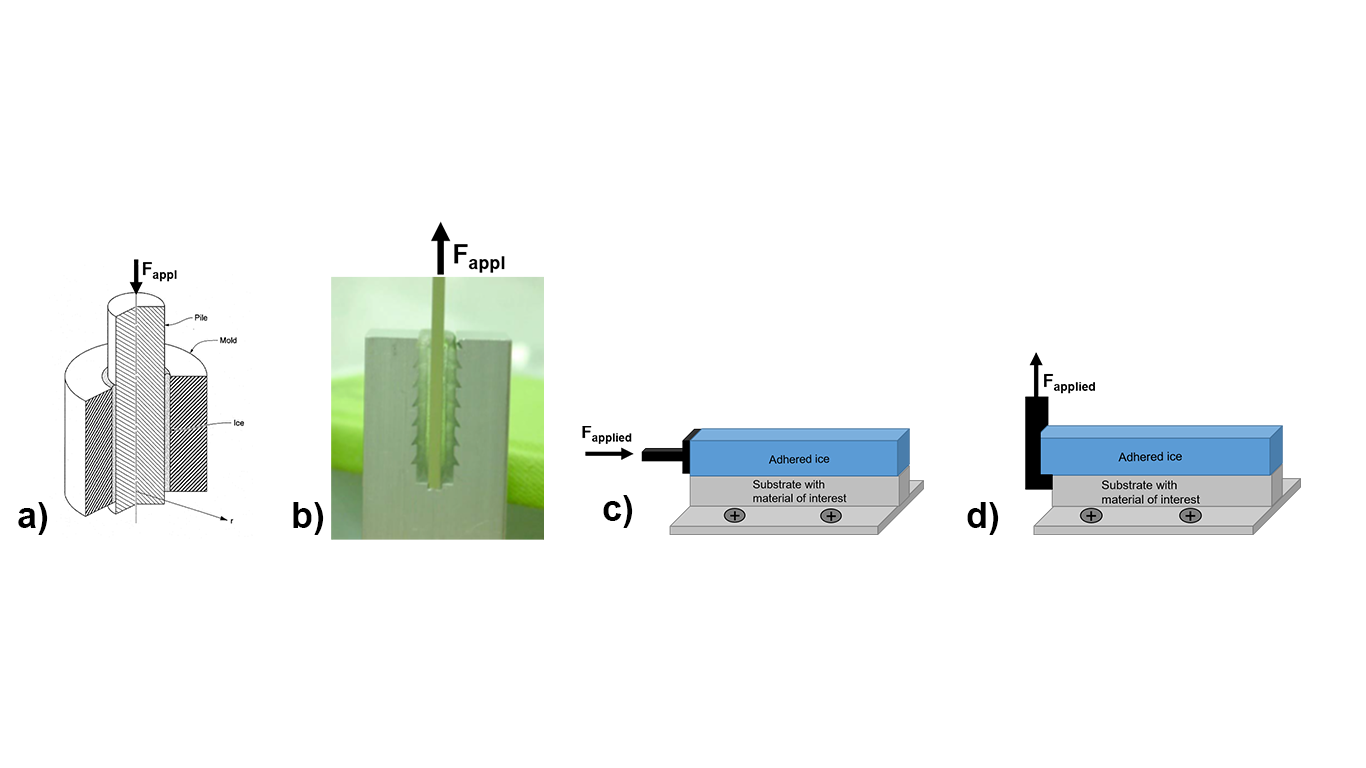

ERDC-CRREL has a versatile set of ice adhesion testing methods that can both serve as an index test for comparing a set of samples during the R&D phase of a project or as a more quantitatively rigorous measurement on promising candidate coatings for low ice adhesion applications. Now known as an industry standard, the Zero Degree Cone Test (ZDCT, Figure 3a)3 is widely used as an index test for screening the adhesion of freshwater ice to coatings under development. The Double Lap Shear Test (Figure 3b)4 is an ASTM standard test index test (ASTM D3528) that is configured to assess a flat test coupon (planar interface). The Peel Test (Figure 3c,d) uses an open planar configuration and thus can be used with saline spray ice and accretion ice in addition to freshwater polycrystalline ice. Furthermore, the Peel Test can be configured for either Mode I tensile or Mode II shear loading (Figure 3c,d).

|

|

Figure 3. Ice adhesion testing configurations available at CRREL: (a) Zero Degree Cone Test where ice is grown in the curved interstitial space between the cylindrical pile and mold, (b) Double Lap Shear Test where freshwater polycrystalline ice is grown in the interstitial space between the planar laps, (c) Peel Test configured for Mode II shear testing, and (d) Peel Test configured for Mode I tensile loading. The unconfined placement of the ice in the Peel Test makes this test amenable to a variety of ice types (e.g., saline spray ice and accretion ice).

|

Benefits

CRREL researchers developed a hybrid ice-resistant coating based on commercially available products to protect the main fuel tank of space shuttles. By facilitating ice release at low speeds, this coating protects the bracket surface and adjacent foam. Using the lap shear test, CRREL researchers evaluated its performance and the durability of a range of coatings and were able to identify the optimal coating and curing conditions to achieve optimal ice release performance.5

Success Stories

After the White House issued the “Implementation Plan for National Strategy for the Arctic Region” (NSAR) in January 2014, the Office of the Secretary of Defense, the U.S. Coast Guard, and the Navy have partnered with CRREL to better understand the effects of ice adhesion on both military and civilian structures and to develop and test a variety of preventive surface coatings and deicing methods.

Applied to ship superstructures, wind turbines, and radar antennae, these coatings are intended to reduce ice buildup, inhibit shearing, and increase operation capabilities.

Additionally, CRREL has worked with the U.S. Coast Guard to test saline spray ice adhesion to fabrics and with numerous industry partners to evaluate the performance of low ice adhesion coatings and materials.

Work with Us

Our capabilities and facilities are available to assist you in addressing and solving a variety of cold regions science and engineering challenges. Please consult the Program Lead below for facility usage and rates information. The Program Lead can also provide additional documentation and work with you to customize testing for your particular application.

Force Projection and Sustainment (CEERD-RRH)

U.S. Army Engineer Research and Development Center | Cold Regions Research and Engineering Laboratory

References (also see Related Content box)

- Cold Regions Research and Engineering Laboratory, Ice Engineering, Ch. 20, 2006, EM 1110-2-1612.

- K. Golovin, S. P. R. Kobaku, D. H. Lee, E. T. DiLoreto, J. M. Mabry, A. Tuteja, Science Advances 2016, 2.

- R. B. Haehnel, N. D. Mulherin, Ice in Surface Waters 1998, 14, 597.

- M. G. Ferrick, N. D. Mulherin et al., ERDC-CRREL Technical Reports 2006, TR-06-21.

- M. G. Ferrick, N. D. Mulherin, R. B. Haehnel, B. A. Coutermarsh, G. D. Durrell, T. J. Tantillo, L. A. Curtis, T. L. St. Clair, E. S. Weiser, R. J. Cano, T. M. Smith, E. C. Martinez, Cold Regions Science and Technology 2008, 52, 224.