|

Passive Cooling (Previous Wintertime) |

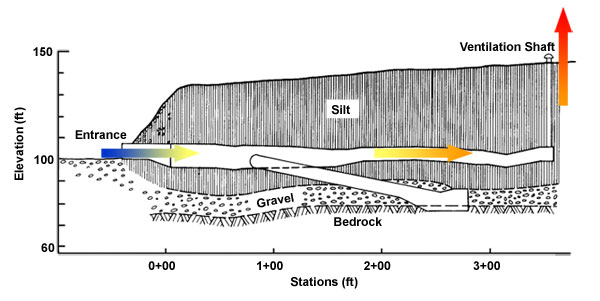

The temperature of the permafrost in the surrounding area of the tunnel is –1.0°C. This temperature is too warm for the frozen silt of the tunnel to support the weight of 15 meters of soil above. Therefore forced cooling has been utilized since nearly the time of initial excavation.

Initially in the wintertime, passive convective cooling was utilized. This was accomplished by drilling a vent shaft from the surface above the tunnel, to the end of the adit. The doors to the portal and a louver on the vent were opened after winter temperatures dropped continually below freezing. Natural convection currents would draft the warmer air of the tunnel up to the surface, pulling cold winter air into the Tunnel through the portal.

The vent shaft was difficult to maintain as surface and ground water would migrate around the vent shaft pipe and completely freeze the shaft shut. Over the years three shafts were drilled to maintain this cooling method. In the early 1990s the last shaft froze shut and this method has not been used since that time.

Passive cooling was used in the wintertime. |

Image of external vent at end of tunnel. |

|

Refrigeration (Sumertime) |

Return to Top |

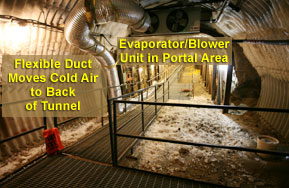

Compressor/Refrigerant Pump Building. |

The warm air temperatures of summer require that a mechanical chilling unit be utilized to maintain the tunnel interior temperature at approximately –4°C. The system is comprised of a compressor unit and refrigerant pump located in a small building outside of the tunnel. The chilled liquid refrigerant is circulated to an evaporator/blower unit which hangs from the ceiling of the portal area and blows the cold air into the tunnel. Engineers are now moving some of the cold air expelled by the evaporator/blower unit to the rear of the adit with the use of flexible ductwork and an inline blower.

|

Forced Air Ambient Cooling (Current Wintertime Method) |

Return to Top |

Cooling Inside Tunnel—Blower/Evaporator Unit with duct to carry cold air to the back of the tunnel. |

The compressor and pump are shut down for the winter due to the high cost of operating this system. The flexible ductwork used in the summertime to move air to the rear of the adit is then used to pull the cold winter ambient air into the tunnel. This is accomplished by re-locating the ductwork to pull air through a vent near the portal door. A temperature control is utilized to shut the blower off in the event the winter temperature rises above freezing.